Technology

At Kumar Steels we use latest modern and automated Technology in the manufacturing of leaf springs. The manufacturing process and the technique carried out at our Works is detailed below. Leaf springs at first are sheared to the required lengths using shearing machine, after that they are subjected to various processes like center punching, end cutting,eye rolling for main leaf, cover/wrapper rolling for 2nd leaf, taper rolling for parabolic leaf spring,leaf spring assembly for multi leaf spring and so on.

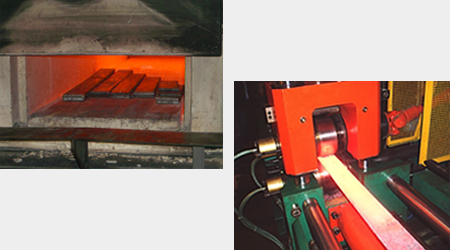

End Heating Furnace for Taper Rolling and Eye Rolling

Firstly leafs are fed to a small furnace to heat the ends. Taper Rolling machine are available for the manufacture of Parabolic springs. Then leafs are passed on the taper rolling machine, where the parabolic curve is created on the leaves. This operation is fully controlled by the skilled operators.

Eye Rolling & Hardening Furnace

The main leafs after heating the ends are then fed to the eye rolling machine for eye formation . We have an automated eye rolling and lab cutting machine for the main, second and other leaves Main leafs are made with precision and checked simultaneously for spring pin fitment After that leaf springs are fed to walking beam furnace for heat treatment where they are heated to 1000 degree Celsius and quenched subsequently

Cambering Machine & Tempering Furnace

After This the spring leaves are placed on a 8 station cambering tool and given a hot camber to a predetermined curvature and simultaneously quenched hardened by the rotation of the drum type cambering machine into the quenching oil bath. The spring leaves are then fed into a tempering furnace, passing through various temperature controls, to relieve the stresses developed due to oil hardening. After tempering, the spring leaves are checked to ensure that they have attained the required hardness using brinell hardness testing machine.

Shot Peenning Machine

Next, the spring leaves are passed through a shot peenning machine, which induces a residual compressive stress on the surface, thereby increasing the fatigue life of the spring.